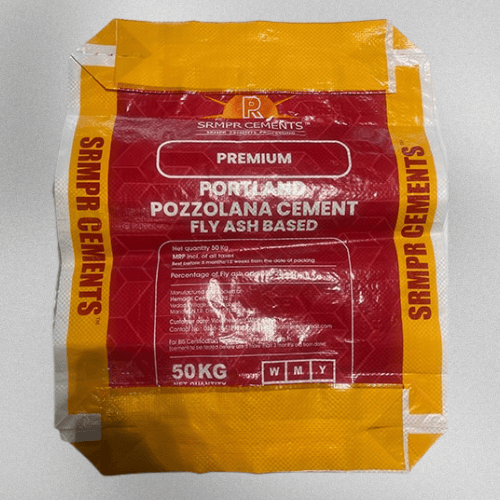

BOPP Block Bottom Bags – Stability and Strength in Packaging

Both our BOPP Block Bottom Bags and our fixed dispensing packages are created to provide maximum stability, easy stackability, and durability to packaging in the industry and rates of sale. Best filling, storage, and stacking all with ease through the innovative block-bottom construction, which minimizes spoilage and handling problems. They are made from high-quality material of BOPP co-operative that confers to the bags exceptional tear resistance and dimensional stability as well as unexpected moisture qualities that are worth retaining in grains, chemicals, and other heavy mass merchandise.

Customizable BOPP Block Bottom Bags for Industry Efficiency

There are many sizes, finishing of laminations, and printing available options when it comes to Lakhotia Polyfab BOPP Block Bottom Bags. They merge the characteristics of high tensile strength, puncture resistance, and UV stability with a stable base design to allow safe handling, efficient logistics, and extended transportation distance. The ability of these bags to support branding using high-quality and lively prints, in addition to being functional and durable, is also a major benefit to businesses using them.

BOPP Block Bottom Bags Manufacturer in India

Our Improved BOPP Block Bottom Bags are in line with sustainability in packaging due to their lightweight and the addition of high mechanical strength. Waterproof, wear-resistant, and environmental stress-resistant: they can be used repeatedly, stacked, and stored in warehouses. Applicable to domestic and export markets, these bags offer non-prohibitive and high-capacity bulk items, configuring solutions that provide safety in vending products, facilitate their operations, and extend their profitability.

Why Choose Our BOPP Block Bottom Bags

Stable & Stackable Design

High Tensile Strength

Tear & Puncture Resistant

Moisture & UV Protected

Vibrant Printing Capable

Reusable and Eco-Friendly

Custom Coating & Lamination